T-Rex Series Wood Chipper is a special equipment for producing wood chips, which is widely used in biomass energy industry raw material production and biomass power plant fuel storage.

| Model | Capacity | Power (KW) | Inlet Size (MM) | The knife Number | Weight (T) |

|---|---|---|---|---|---|

| TR-A6585 | 25 – 40 | 110+3+32.5+1.5 | 850X500 | 3 | 6.5 |

| TR-A65120 | 40 – 80 | 160+4+4+2.2+1.5 | 1200X500 | 5 | 8.84 |

| TR-A8085 | 70 – 150 | (160-220)+7.5+3 | 844X620 | (6) | 10.5 |

| TR-A80130 | 100 – 200 | (160-315)+11+3 | 1300X620 | (10) | 15.5 |

| Model | Capacity | Power (KW) | Inlet Size (MM) | The knife Number |

|---|---|---|---|---|

| TR-C90150 | 7-14 | 250×2 | 1470 | 32 |

| 6-12 | 200×2 | 1470 | 32 | |

| 5-10 | 315 | 1470 | 32 | |

| TR-C2000 | 8-16 | 315×2 | 1870 | 48 |

| Model | Capacity (T/H) | Power (KW) | Fixed Knives Qty (PCS) | Flying Knives Qty (PCS) |

|---|---|---|---|---|

| XP1000 | 5-10 | 75 | 1 | 4 |

| XP1300 | 7-15 | 110 | 1 | 4 |

| Model | Rotor working diameter | Power (KW) | Qty of blades (pcs) |

|---|---|---|---|

| ZLFS1200 | 1200×980 | 90-160+1.5+4 | 120 |

| ZLFS1200 | 1500×1000 | 160-200+1.5+4 | 120 |

| Model | Rotor working diameter | Power (KW) | Qty of blades (pcs) |

|---|---|---|---|

| ZLFS1200 | 1200×980 | 90-160+1.5+4 | 120 |

| ZLFS1200 | 1500×1000 | 160-200+1.5+4 | 120 |

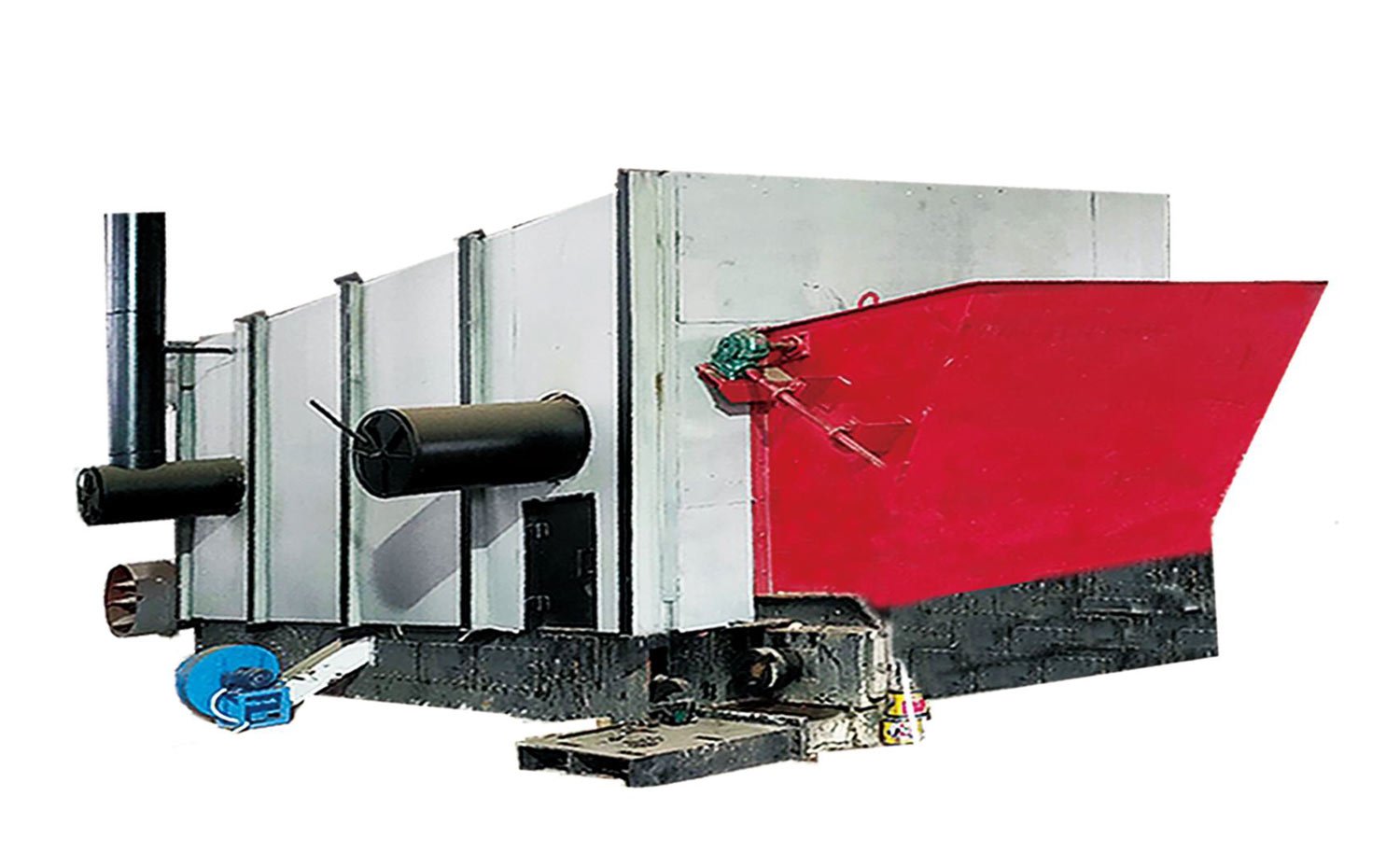

| Model | Caloric value (kcal) | Fuel consumption (kg/h) |

|---|---|---|

| LPRF240 | 240 | 600-700 |

| LPRF300 | 300 | 900-900 |

| LPRF360 | 360 | 900-1000 |

| LPRF480 | 480 | 1100-1300 |

| LPRF600 | 600 | 1400-1500 |

| LPRF800 | 800 | 1900-2000 |

| LPRF1000 | 1000 | 2400-2500 |

| Model | Shaft Speed (r/min) | Qty of Hammers (pcs) | Tube Diameter (m) |

|---|---|---|---|

| XQJ200 | 2120 | 20 | 2 |

| XQJ250 | 1800 | 18 | 2.5 |

| XQFS75x100 | 2780 | 96 | 2 |

| XQFS75x150 | 2780 | 156 | 2.5 |

| XQFS75x150 (S) | 2780 | 312 | 3.0 |

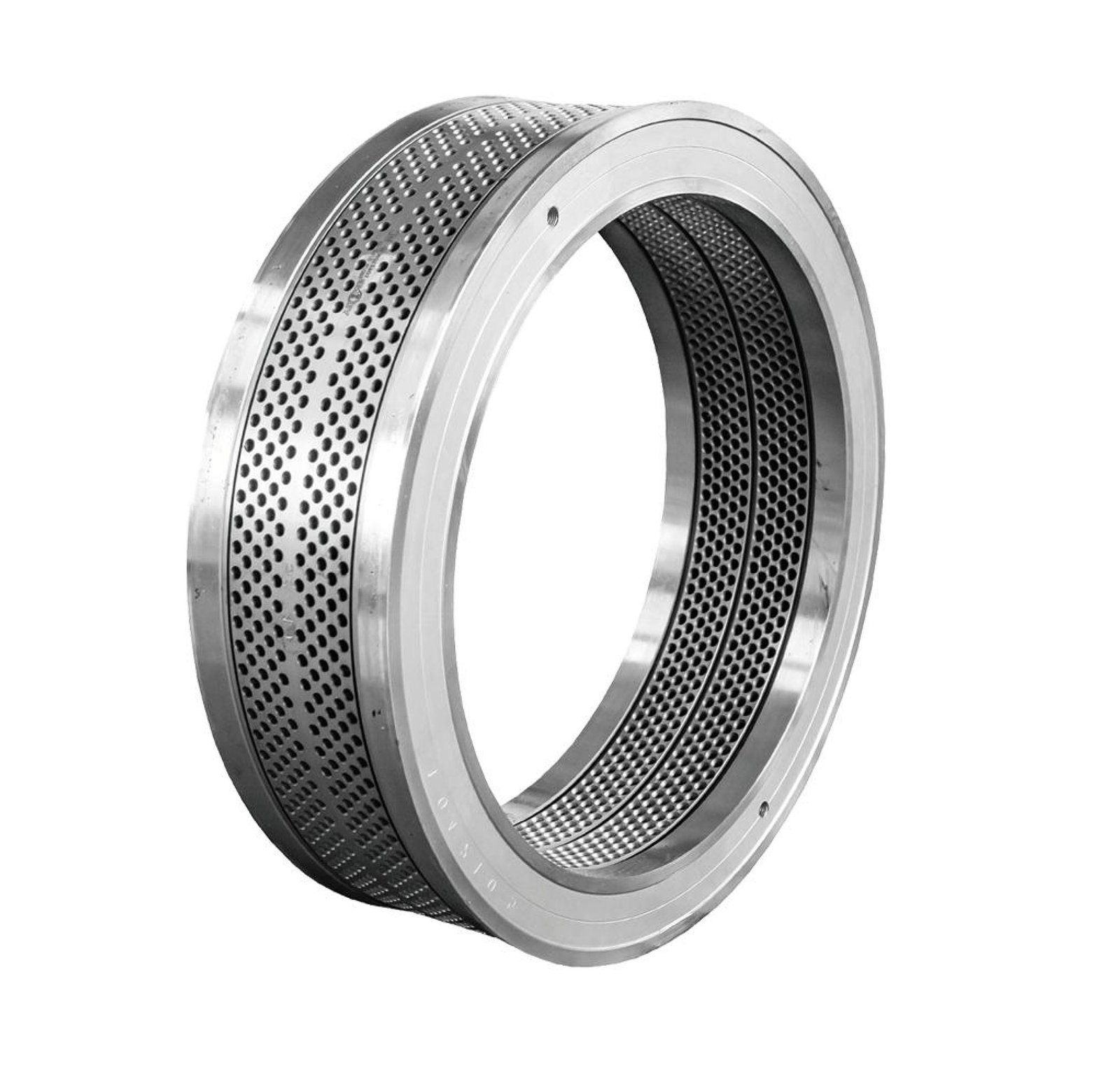

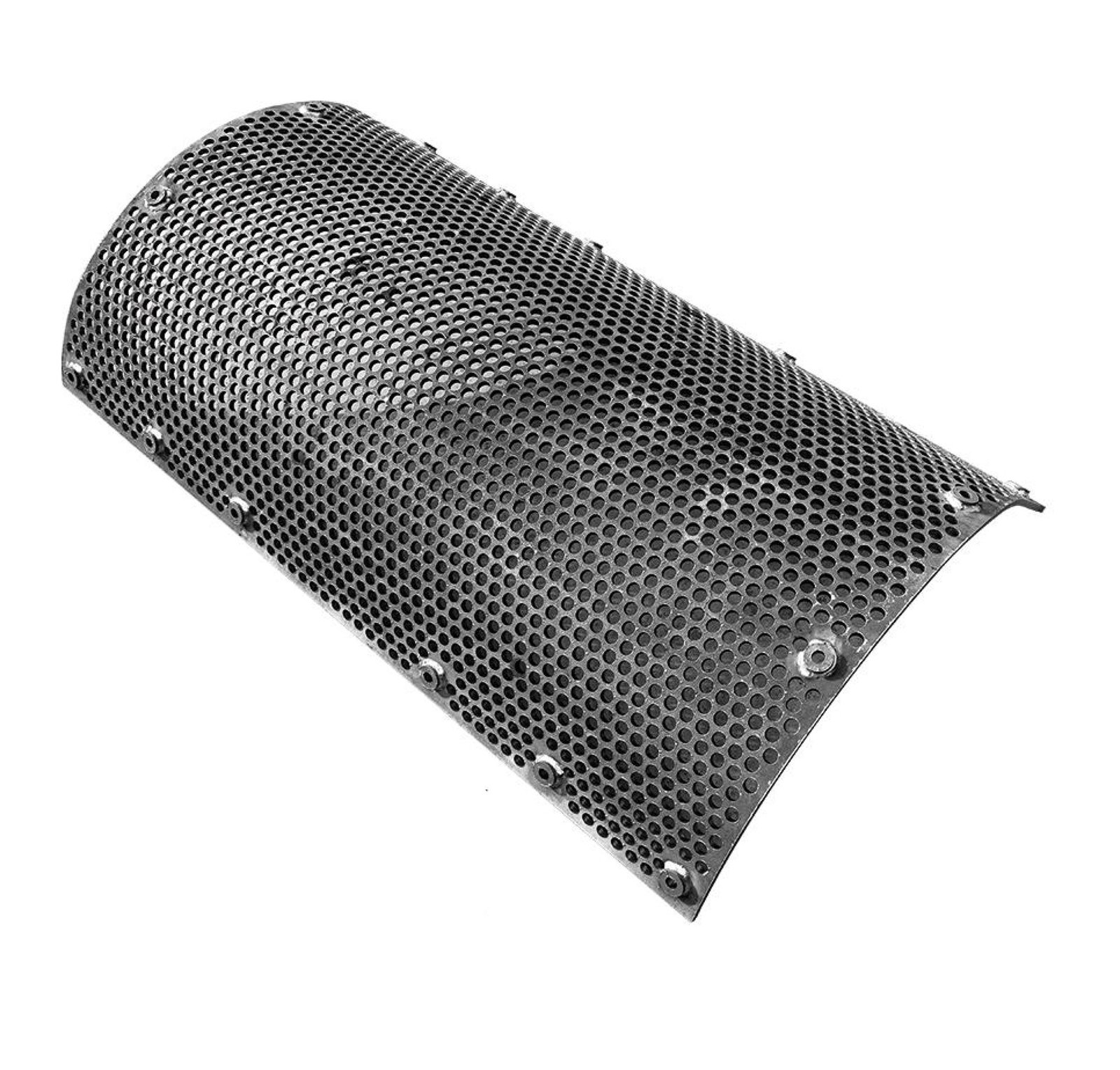

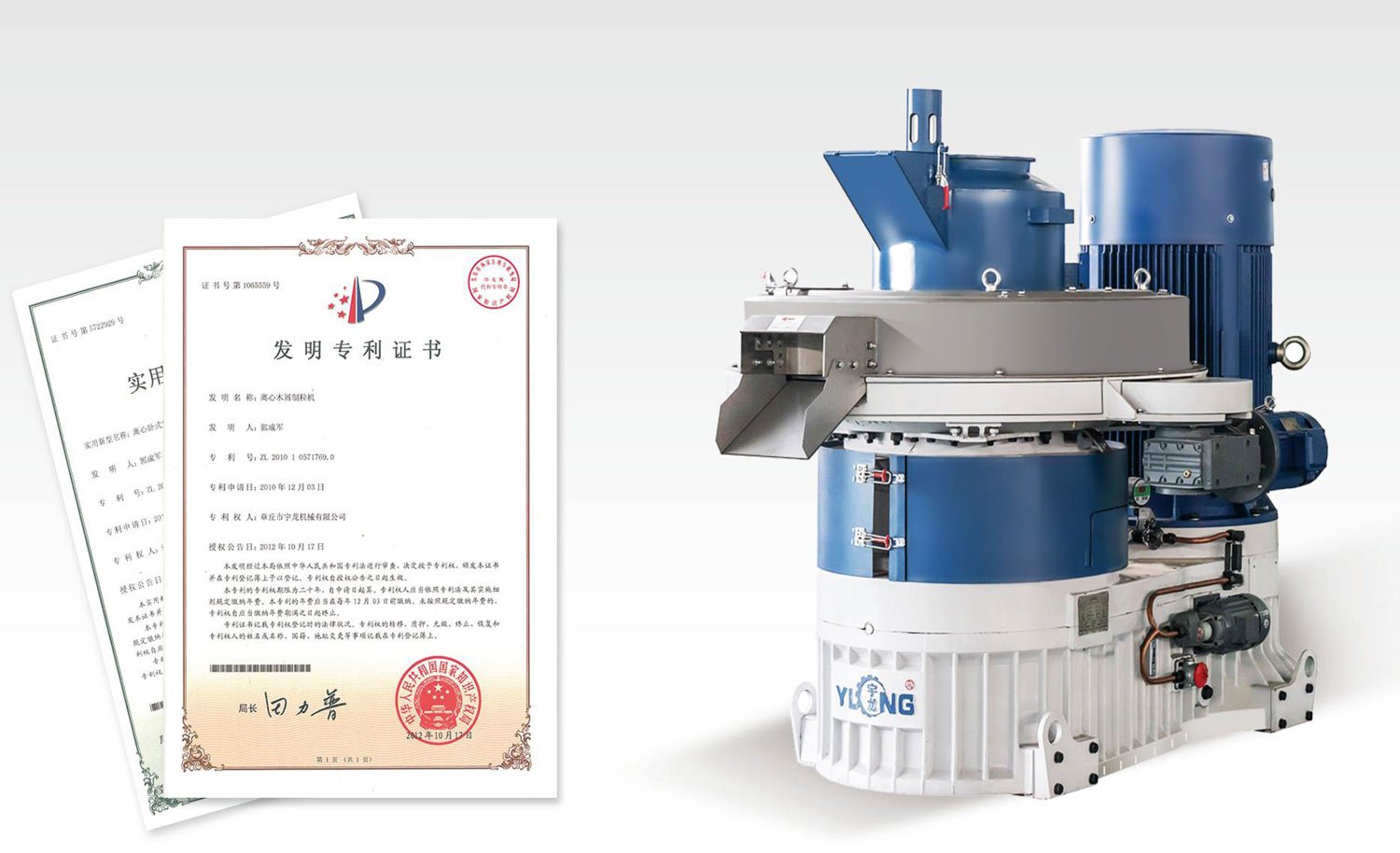

Ring Die: ultra-wear stainless steel, vacuum quenching, uniform hardness, high strength, long lifetime.

Roller: surface stacking super wear resistant alloy process, lifetime equal to ring die. Roller bearings: high-temperature resistant bearings, enhanced compact arrangement roller, raceway optimization structure, high loading capacity, long lifetime.

Power input: Adopt flexible connection mode, no lubrication required, low noise.

Reducer: with lubrication cooling system, oil pressure real-time monitoring, worry-free all-day long-time operation; 5 times overworking conditions design of multi-stage hard helical gear, stable operation; bearing clearance can be adjusted with no remove machine, save maintenance time.

Discharging system: Innovative rotary disc discharging system, all transmission parts are external, free from high temperature and corrosive environment, and the non-moving parts inside the discharging shell are made of stainless steel, with stable discharging and long service life.

| Model | Caloric value (kcal) | Fuel consumption (kg/h) |

|---|---|---|

| LPRF240 | 240 | 600-700 |

| LPRF300 | 300 | 900-900 |

| LPRF360 | 360 | 900-1000 |

| LPRF480 | 480 | 1100-1300 |

| LPRF600 | 600 | 1400-1500 |

| LPRF800 | 800 | 1900-2000 |

| LPRF1000 | 1000 | 2400-2500 |

| Model | Model | Size (M M) | Weight (T) | Weight (T) |

|---|---|---|---|---|

| XGJ1200 | 710/800/1000KW | 4800X2500X3600 | 40 | 10-20 |

| Model | Calorific Value | Equivalent Power | Fuel Consumption | Fan Power | Feed+automatic+discharge |

|---|---|---|---|---|---|

| YLR-60Q | 60 | 0.7 | 150 | 2.95 | 1.9 |

| YLR-120Q | 120 | 1.4 | 300 | 606 | 1.9 |

| YLR-240Q | 240 | 2.8 | 600 | 9.7 | 4.15 |

| YLR-360-Q | 360 | 4.2 | 900 | 15 | 4.85 |

| YLR-480Q | 480 | 5.6 | 1200 | 18 | 6.5 |

| YLR-600Q | 600 | 7 | 1500 | 22.5 | 7.1 |

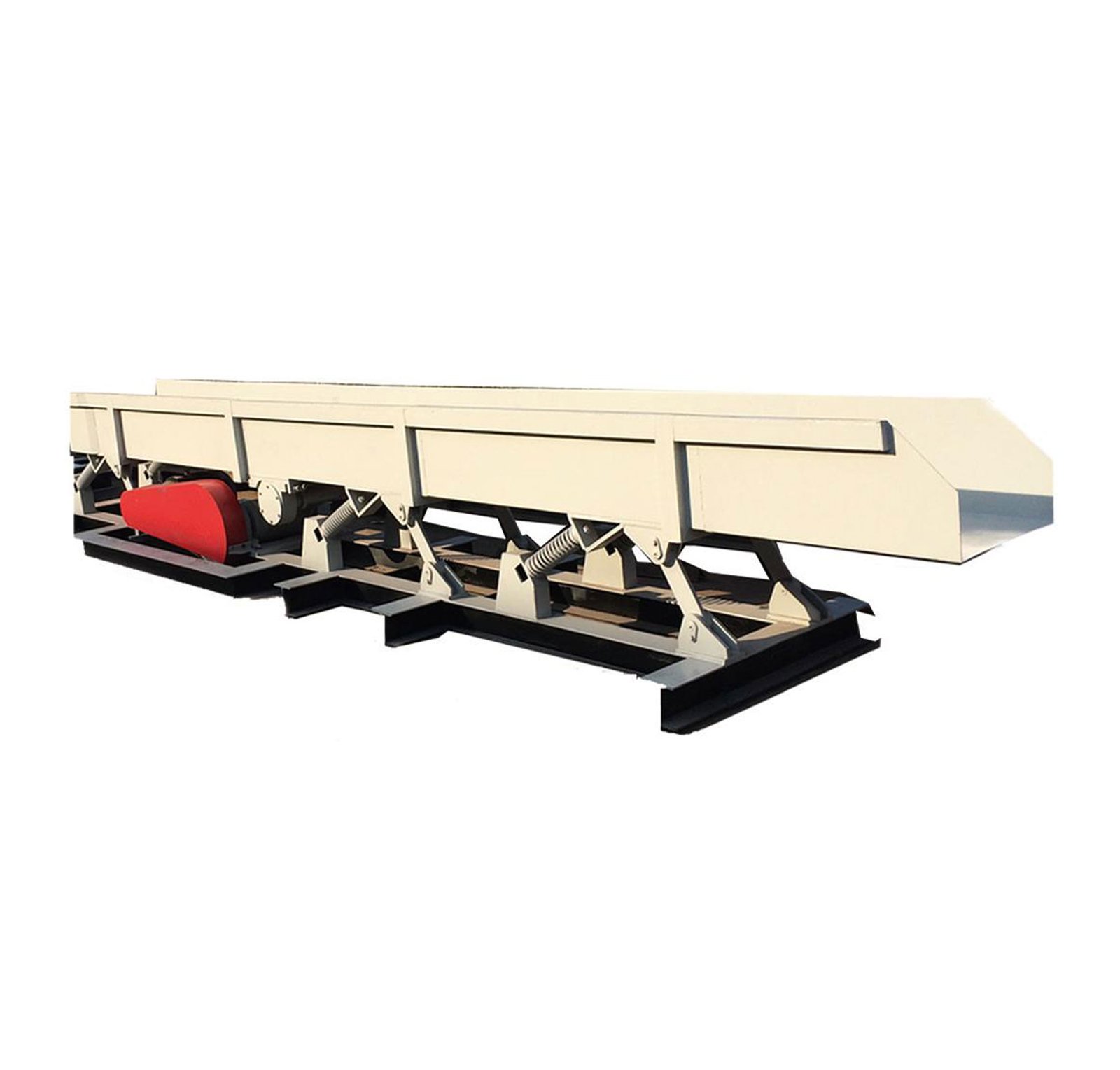

The machine has a unique cooling mechanism, the cooling air and the pellets move in reverse, so that the materials are gradually cooled from bottom to top. It avoids the surface cracking of pellets caused by quenching in general vertical coolers. It also avoids problems such as pellets cracking caused by the difficulty of dissipating moisture and heat in the core of the pellets during the cooling time.

| Model | Capacity (T/H) | Equivalent Power | Fuel Consumption | Fan Power | Feed+automatic+discharge |

|---|---|---|---|---|---|

| SKLN-1.5 | 1-2 | 1.1+0.18+5.5 | 1.5 | ≥6-10 | ≤3-5 |

| SKLN-2.5 | 2-3 | 2.2+0.18+11 | 2.5 | ≥6-10 | ≤3-5 |

| SKLN-4 | 4-6 | 2.2+0.25+22 | 4 | ≥6-10 | ≤3-5 |

| SKLN-6 | 7-10 | 3+0.25×2+37 | 6 | ≥6-10 | ≤3-5 |

| SKLN-8 | 10-15 | 3+0.25×2+55 | 8 | ≥6-10 | ≤3-5 |

| SKLN-10 | 15-20 | 3+0.25×2+75 | 10 | ≥6-10 | ≤3-5 |

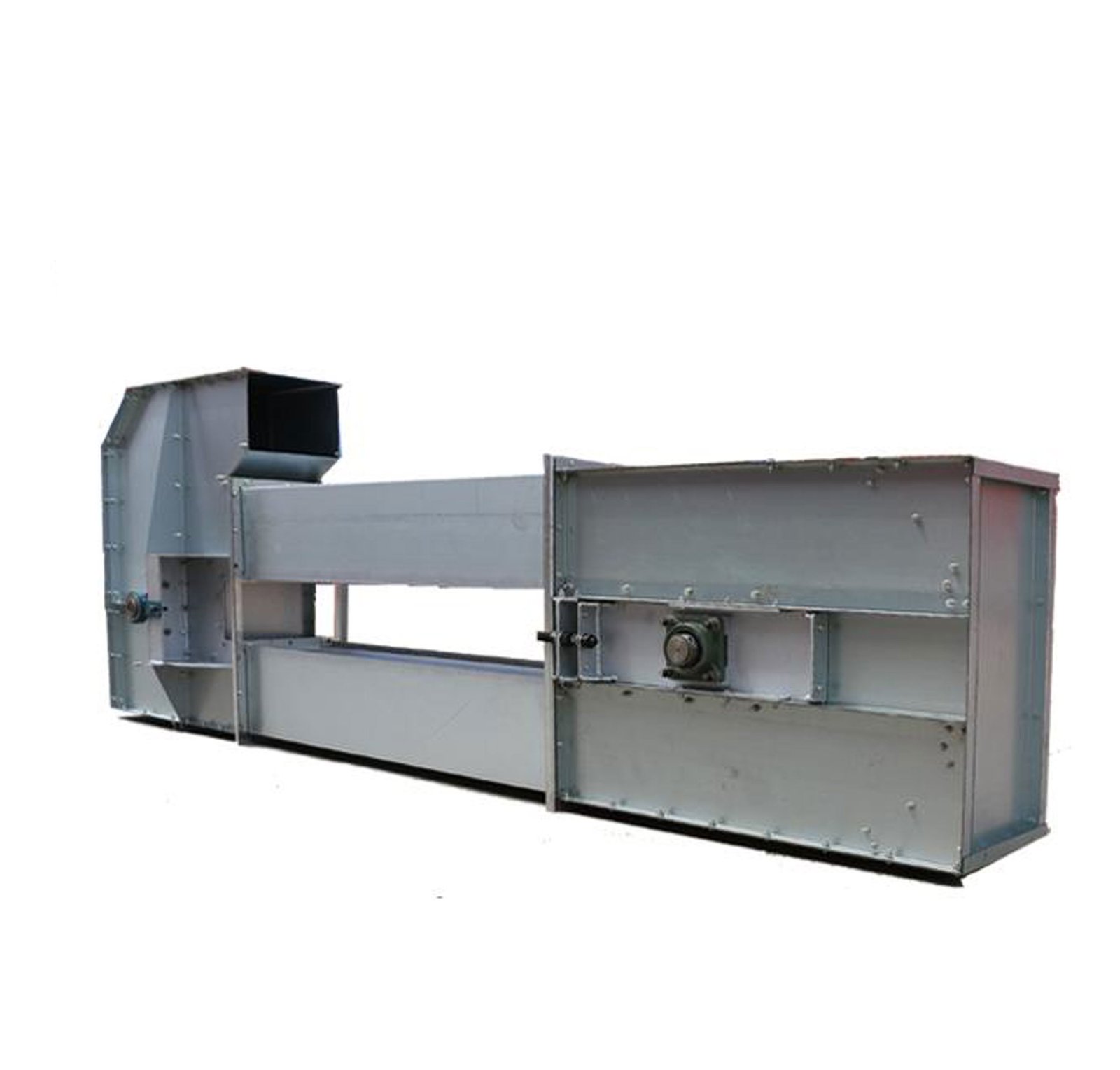

This series shaking staged screener works stably with high efficiecy. Feature of machine is quite compact, less space occupation, convenient installation and maintenance, and replace screen easily. Mainly used in energy, food, feed, chemical, pharmaceutical and other industries.

| Model | Capacity (T/H) | Power(KW) | Times/Min | Excitation Force (N) | (MM) |

|---|---|---|---|---|---|

| SKFZ60x2c | 1-2T | 0.25 | 920 | 4000 | 1000X600 |

| SKFZ80x2c | 2-4T | 0.25 | 920 | 5000 | 1500X800 |

| SKFZ110x2c | 3-6T | 0.37 | 920 | 4000 | 1800X1000 |

| SKFZ150x2c | 3-6T | 0.37 | 920 | 6000 | 2000X800 |

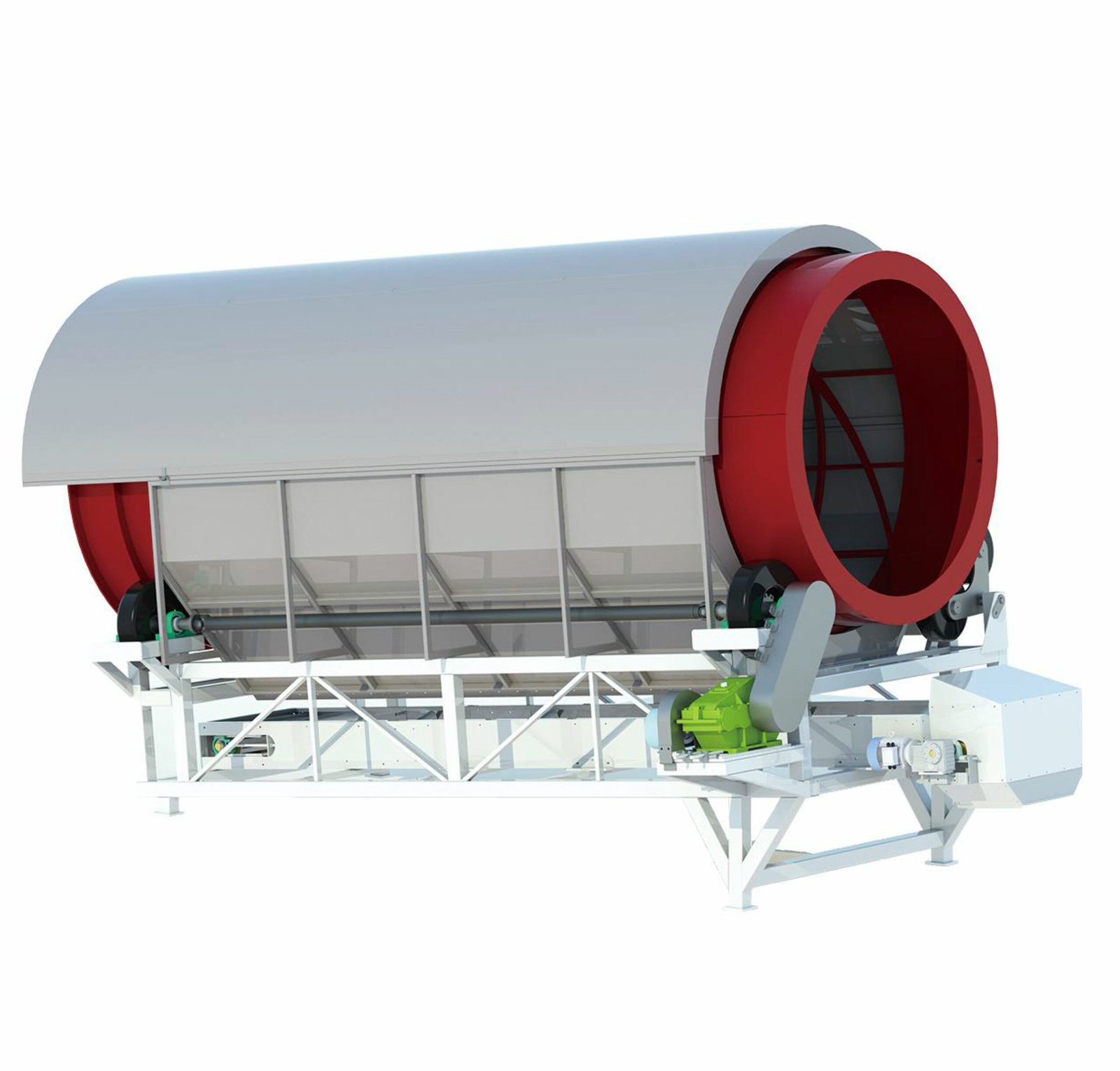

| Model | Capacity (T/H) | Power(KW) |

|---|---|---|

| GTS1X2 | 1-2 | 1.5 |

| GTS1.2X2 | 2-3 | 1.5 |

| GTS1.5X2.5 | 3-5 | 1.5 |

| GTS1.8X3 | 5-7 | 2.2 |

| GTS2.2X4 | 8-10 | 4.0 |